Cleaver- Brooks offers a full line of integrated boiler controls, communication systems, packaged water controls, water level controls and stand-alone controls for new or retrofit applications, designed to increase efficiency, reduce fuel costs and decrease emissions to get the most out of your boiler room.

Boiler Controls

Cleaver-Brooks Controls

Integrated Boiler Controls

PLC-based, with capabilities for a Hydronic System Control for condensing, non-condensing and hybrid boiler applications to advanced boiler room controls that will aid in maximizing efficiency and save fuel. Designed and optimized to work with our Cleaver-Brooks systems however, virtually any system can benefit from the addition of a control for efficient, money-saving boiler room performance.

Learn more about Integrated Boiler Controls

Communication Systems

A key component in the process of transferring data from boiler controls to external building automation, SCADA (Supervisory Control and Data Acquisition) or remote monitoring systems.

Learn more about Communication Systems

Industrial Controls

With a multitude of features and capabilities, we’ll help you custom design your Cleaver-Brooks industrial control unit to meet the needs of your specific boiler system.

Learn more about Industrial Controls

Packaged Water Controls

Engineered to work seamlessly with other Cleaver-Brooks boiler system controls, our packaged water controls monitor and manage all of your system’s water-related touch points, including pumps and level controls.

Learn more about Packaged Water Controls

Stand Alone Controls

Achieve maximum burner efficiency with our stand-alone control products. With their user-friendly setup and operation, these controls will improve burner performance quickly and easily.

Learn more about Stand Alone Controls

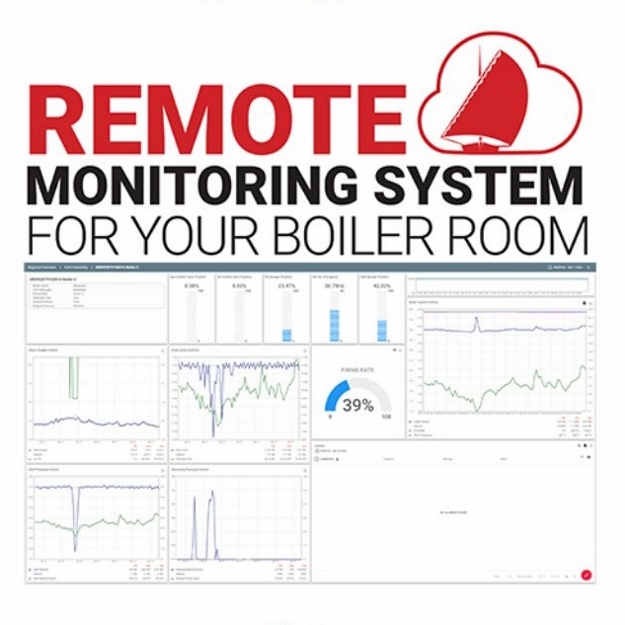

Prometha

Connected Boiler Solutions

Cleaver-Brooks innovative and technologically advanced solution offers users the ability to remotely monitor boiler systems from anywhere. Ideal for any industry, this next-level communication provides alerts and actionable insights that help increase reliability, efficiency, safety and sustainability in the boiler room.

Learn more about Prometha

Video Link: Prometha by Cleaver-Brooks

Preferred Instruments

New or retrofit control system solutions for boilers, burners, and fuel oil designed with PLC or proprietary controller to meet the needs of the end user.

Preferred Instruments

Cloud Platform

The Preferred Instruments Cloud Platform offers three levels of secure remote monitoring with alerts and updates to your mobile phone or computer. The Preferred Cloud allows a facility manager to view their equipment on a secure webpage and send alerts and updates to mobile phones or computers.

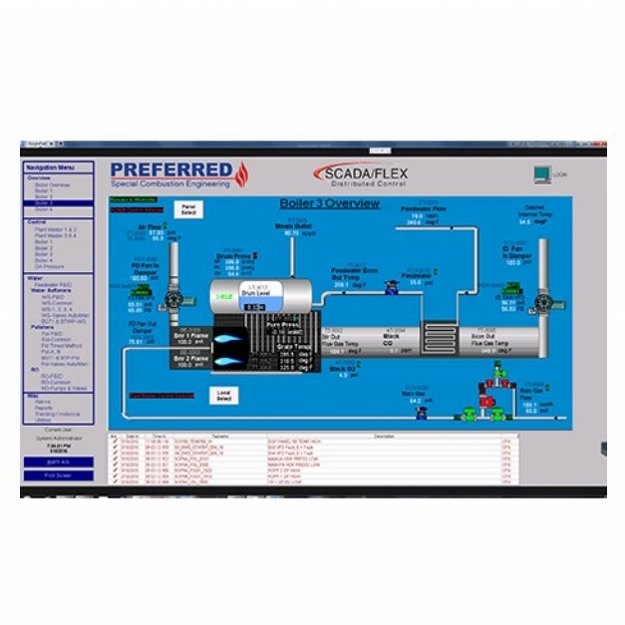

SCADA/Flex

Control Systems

SCADA (Supervisory Control and Data Acquisition) systems are designed to provide remote operation, graphic display of information, alarm message display, report generation, historical trending and remote controller tuning.

BurnerMate Programmable

Logic Controller (BMPLC)

This control system gives you full control over your boiler. Parameter based, integrates with your equipment, the standard programs allow the BMPLC to be delivered with a short lead time.

BurnerMate Universal

(BMU)

Designed for both firetube boilers and watertube boilers, this total boiler control system utilizes the latest technology in microprocessors to give you the highest quality in combustion control for your boiler room.

PCC-IV Digital

Multiple Loop Controller

The PCC-IV boiler or multiple loop process controller has been designed to seamlessly replace the PCC-III in hardware and software designs, with upgraded technology and increased longevity.

Plant Wide Controller

(PWC)

The PWC is a complete plant monitoring, control and communication interface. With state-of-the-art equipment sequencing, control, and monitoring, it combines innovative ease of operation, communication and expansion capabilities with boiler plant control application expertise.

Feedwater Center

(FWC)

The FWC is designed to control the surge tank, Deaerator (DA) tank, transfer pumps, and feedwater pumps (on-off or VSD) to improve water quality and feedwater system reliability.

BurnerMate TS

Boiler Control System

BurnerMate TS is a custom-programmable boiler control and flame safeguard system that includes one or two DCS-IV loop controllers and a flame safeguard microprocessor communicating via Modbus with a 10” or 15” OIT touch screen. It has software that runs on your Windows based PC that allows you to set the BMU from your laptop.

Chief Dispatcher

Boiler Plant Master

The Chief Dispatcher is an advanced boiler sequencing, communication and monitoring system, providing lead-lag for up to ten boilers. Off the shelf standard modulating lead/lag applications can be expanded to control circulating water variable speed pumps and isolation valves while monitoring the flame safeguards and boiler control systems.